In most biomedical device companies, the first steps to success don’t require a four-year degree, according to Jon Olson, Director of ProWork Training at Anoka Technical College. “Manufacturing jobs do require bright, skilled, problem-solving people,” he said. “You do use math everyday–not just adding and subtracting. It’s trigonometry.”

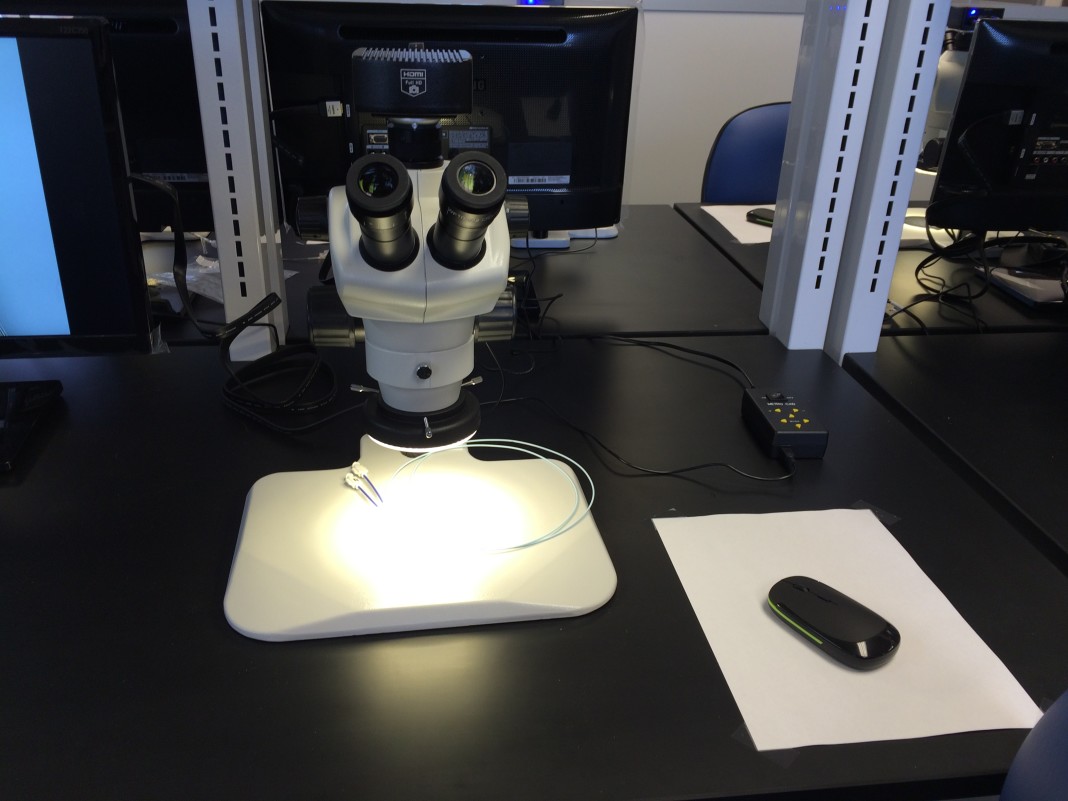

Medical device manufacturing jobs will typically require microscope work, blueprint reading and metrology–the accurate measurement of parts that are often too small to be seen with the naked eye. All of those skills are covered in the Anoka Tech introductory course in Medical Device Manufacturing..

As in many careers, lots of small things contribute to job satisfaction. Are you willing to wear a beard net? Can you see yourself going to work without makeup? The Anoka Technical College Medical Device program covers workstation ergonomics. Olson said the proper adjustment of the workstation is critical if you’re going to spend several hours a day looking through a microscope. But it’s not just the technical skills, Olson said. “It’s about communication, working on teams, problem-solving.”

Ultimately, Olson said, students report one big area of satisfaction in a medical device career: It’s about making a difference. “Students say, ‘My grandfather has a pacemaker, or I have an insulin pump.’ They know what they do everyday contributes to the health and quality of life of millions of people.”